6082 H-Shaped Aluminum Bar

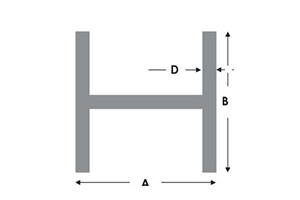

A: 10 mm ~ 300 mm B: 20 mm ~ 160 mm

D: 1 mm ~ 10 mm

Length : 3000 mm ~ 6000 mm

Place of Origin : China

MOQ : 1 ton

Packaging: Export standard packaging

The 6082 H-shaped aluminum bar from Bory Metal is engineered for demanding applications where both precision and durability are critical. This high-strength aluminum alloy is well-suited for CNC machining, allowing for the creation of complex parts with tight tolerances and smooth finishes. The H-shaped profile provides excellent load distribution, making it ideal for structural components and supports in heavy machinery, vehicles, and construction projects.

Key Features

Precision Machinability: The 6082 alloy is highly machinable, making it perfect for CNC operations where intricate designs and high accuracy are required. This ensures that components manufactured from this bar meet the exacting standards of industries like aerospace and automotive.

Superior Strength and Durability: With its excellent mechanical properties, the 6082 H-shaped bar can withstand heavy loads and harsh conditions, making it ideal for structural supports and load-bearing applications.

Corrosion Resistance: The natural corrosion resistance of the 6082 alloy makes it suitable for use in environments where exposure to moisture, chemicals, or saltwater is a concern, ensuring long-lasting performance.

Custom Packaging: Each bar is cut and packaged according to your specifications, ensuring that the product arrives in perfect condition and ready for immediate use in your projects.

Applications

CNC Machining: Ideal for producing high-precision components used in automotive, aerospace, and industrial machinery, where accurate dimensions and superior surface finishes are essential.

Structural Components: Used in the construction of load-bearing frameworks, supports, and other critical infrastructure elements where strength and stability are required.

Heavy-Duty Machinery: Suitable for manufacturing parts that must endure significant stress and wear, including gears, shafts, and brackets in heavy machinery.

Automotive and Aerospace: Perfect for creating lightweight yet robust components that contribute to fuel efficiency and safety in vehicles and aircraft.

Chemical Composition (%) | |||||||||||||

Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Other | Al | ||

6082 | 0.7~1.3 | 0.50 | 0.10 | 0.40~1.0 | 0.6~1.2 | 0.25 | — | 0.20 | — | 0.10 | — | 0.20 | Rest |

Why Choose Bory Metal?

Professional Technical Guidance: Our team of industry experts is available to provide you with the technical advice and support necessary to choose the best materials for your projects.

Dependable Logistics: With a robust supply chain, we ensure the timely delivery of our products, regardless of order size or complexity.

Customized Solutions: We offer bespoke manufacturing services to meet your project’s specific requirements, from tailored dimensions to specialized treatments.

Commitment to Sustainability: Bory Metal practices eco-conscious manufacturing, utilizing sustainable processes and materials in the creation of our aluminum products.