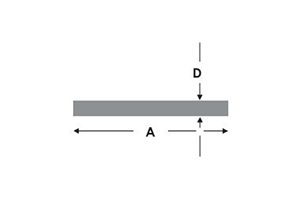

7075 Flat Aluminum Bar

A: 10 mm ~ 200 mm D: 2 mm ~ 200 mm

Length : 3000 mm ~ 6000 mm

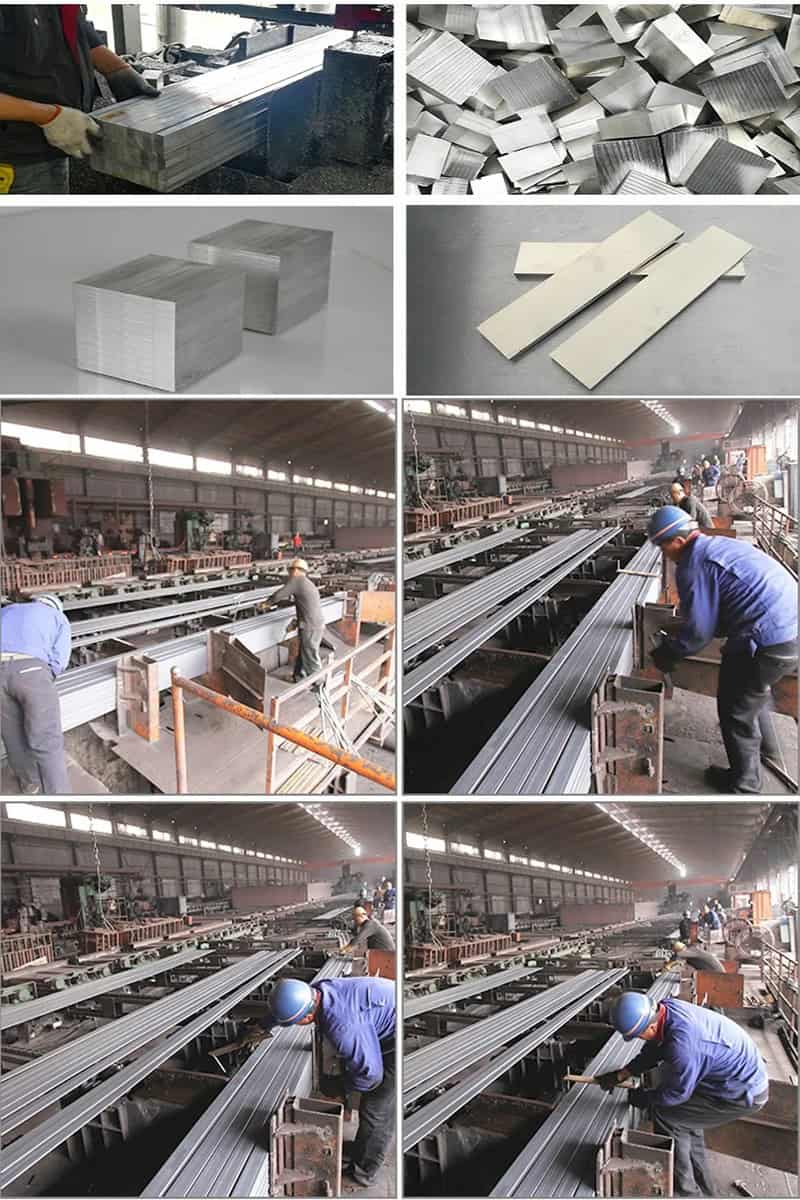

Place of Origin : China

MOQ : 1 ton

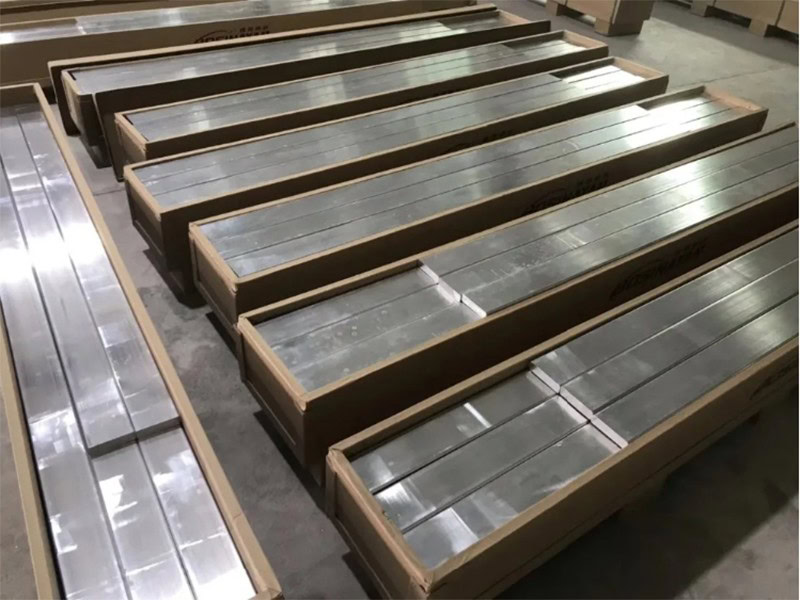

Packaging: Export standard packaging

The 7075 flat aluminum bar is renowned for its exceptional strength-to-weight ratio, making it one of the most sought-after alloys for critical, high-stress applications. This premium-grade aluminum offers a combination of superior tensile strength, hardness, and fatigue resistance, making it a preferred choice for industries such as aerospace, defense, automotive, and high-performance machinery.

As one of the toughest aluminum alloys available, 7075 excels in environments where traditional aluminum would fail under extreme stress or fatigue. It is commonly used in components that require both lightweight properties and maximum strength, ensuring that the structure or product can withstand heavy loads and prolonged use without compromising performance.

Key Features

High Tensile Strength: The 7075 alloy is known for its incredible strength, often compared to steel, while maintaining the benefits of aluminum’s lighter weight.

Superior Fatigue Resistance: This alloy’s ability to endure repeated stress cycles without failure makes it ideal for applications where longevity and reliability are crucial.

Excellent Machinability: The 7075 flat aluminum bar offers excellent machinability, allowing for precise fabrication and customization in complex components.

Corrosion Resistance with Protective Coatings: While the 7075 alloy is less naturally corrosion-resistant than some other aluminum alloys, it performs well when treated with protective coatings, making it suitable for outdoor and marine applications.

Hardness and Durability: Its high hardness levels ensure that this alloy withstands abrasive environments and mechanical wear over time.

Applications

Aerospace Engineering: The 7075 flat aluminum bar is widely used in aircraft structures, wings, and fuselage components where weight savings and high strength are critical.

Defense Industry: Frequently used in military-grade equipment such as armor plates, missile components, and various high-impact parts that require robust performance in extreme conditions.

Automotive Performance Parts: Ideal for racing and performance vehicles, the 7075 alloy is used in chassis components, suspension systems, and other high-stress automotive parts.

Heavy Machinery: Utilized in the production of gears, shafts, and other components that must withstand high loads and continuous operation without failure.

Tooling and Molds: The alloy’s hardness and resistance to deformation make it suitable for industrial tooling, jigs, and molds that demand long-lasting precision and durability.

Chemical Composition (%) | |||||||||||||

Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Other | Al | ||

7075 | 0.40 | 0.50 | 1.2~2.0 | 0.30 | 2.1~2.9 | 0.18~0.28 | — | 5.1~6.1 | — | 0.20 | — | 0.20 | Rest |

Why Choose Bory Metal?

Professional Technical Guidance: Our team of industry experts is available to provide you with the technical advice and support necessary to choose the best materials for your projects.

Dependable Logistics: With a robust supply chain, we ensure the timely delivery of our products, regardless of order size or complexity.

Customized Solutions: We offer bespoke manufacturing services to meet your project’s specific requirements, from tailored dimensions to specialized treatments.

Commitment to Sustainability: Bory Metal practices eco-conscious manufacturing, utilizing sustainable processes and materials in the creation of our aluminum products.