6082 Round Aluminum Tube

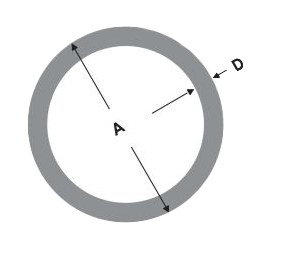

A: 6 mm ~ 1000 mm D: 1 mm ~ 50 mm

Length : 500 mm ~ 6000 mm

Place of Origin : China

MOQ : 1 ton

Packaging: Export standard packaging

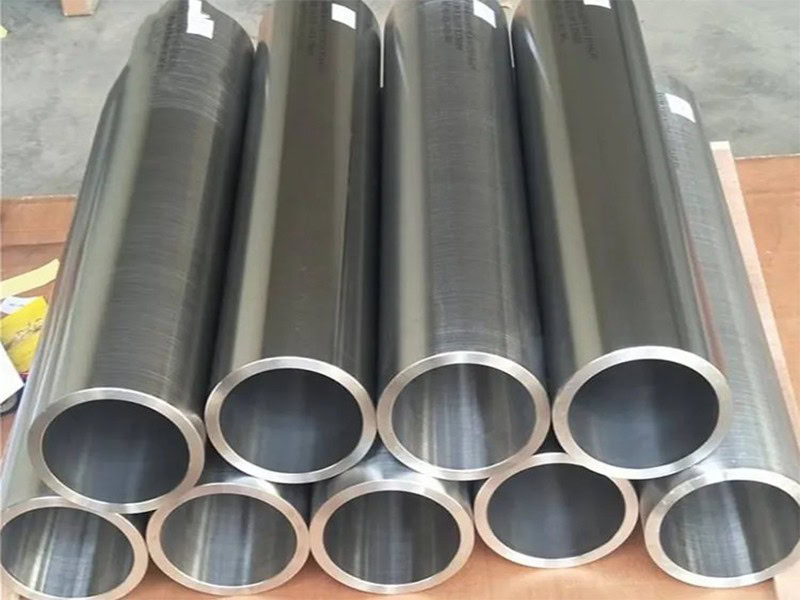

The 6082 round aluminum tube is a premium alloy known for its high strength and excellent resistance to wear and tear. This tube is particularly suited for applications where both structural integrity and precision are paramount. The 6082 alloy is often selected for its ability to withstand heavy loads and resist deformation, making it a go-to material for critical components in engineering and construction. Additionally, its compatibility with various machining processes ensures that it meets the exact specifications required for complex designs.

Key Features

Enhanced Strength: The 6082 aluminum tube is one of the strongest alloys in the 6000 series, offering superior load-bearing capacity for demanding applications.

Precision Machining: This alloy’s excellent machinability allows for high precision in the production of intricate parts and components, ensuring tight tolerances are met.

Fatigue Resistance: The 6082 aluminum tube is designed to perform reliably under repeated stress, making it ideal for dynamic structures and moving parts.

Environmental Durability: With excellent resistance to corrosion and environmental factors, the 6082 tube is well-suited for outdoor and marine applications where durability is crucial.

Applications

High-Performance Structures: Used in the construction of bridges, towers, and heavy-duty frameworks where both strength and flexibility are required.

Precision Engineering: Ideal for the production of detailed mechanical parts, such as gears, joints, and components that require meticulous accuracy.

Automotive and Aerospace: Preferred for critical components in vehicles and aircraft that require high strength-to-weight ratios and exceptional reliability.

Marine Construction: Suitable for use in shipbuilding, offshore platforms, and other marine applications where resistance to seawater and corrosion is essential.

Chemical Composition (%) | |||||||||||||

Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Other | Al | ||

6082 | 0.7~1.3 | 0.50 | 0.10 | 0.40~1.0 | 0.6~1.2 | 0.25 | — | 0.20 | — | 0.10 | — | 0.20 | Rest |

Why Choose Bory Metal?

Strict Quality Control: Our aluminum tubes undergo rigorous quality testing to ensure each batch meets international standards.

Customized Services: We offer tailored solutions based on customer-specific requirements, ensuring the perfect fit for your project needs.

Expert Technical Support: Bory Metal’s experienced technical team is ready to provide professional advice and support for your projects.

Quick Response and Delivery: Our sales and logistics teams are committed to providing fast quotes and timely deliveries to keep your project on schedule.

Reliable After-Sales Service: We provide comprehensive after-sales services, including logistics tracking and rapid resolution of technical issues, ensuring your satisfaction.